Applications

These modules are designed to drive diode lasers, bars and arrays in pulsed, QCW or CW modes.

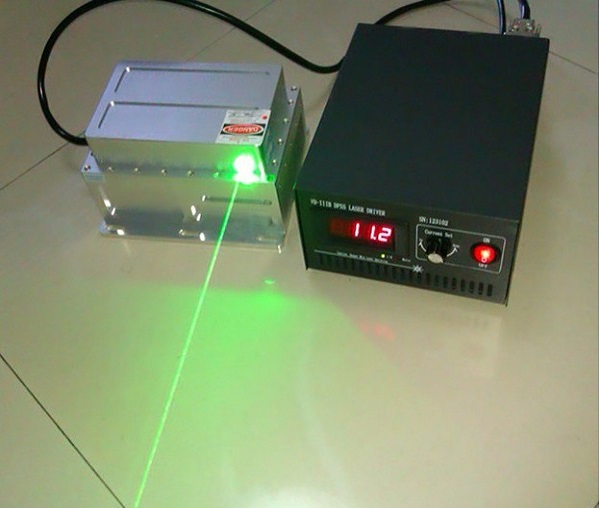

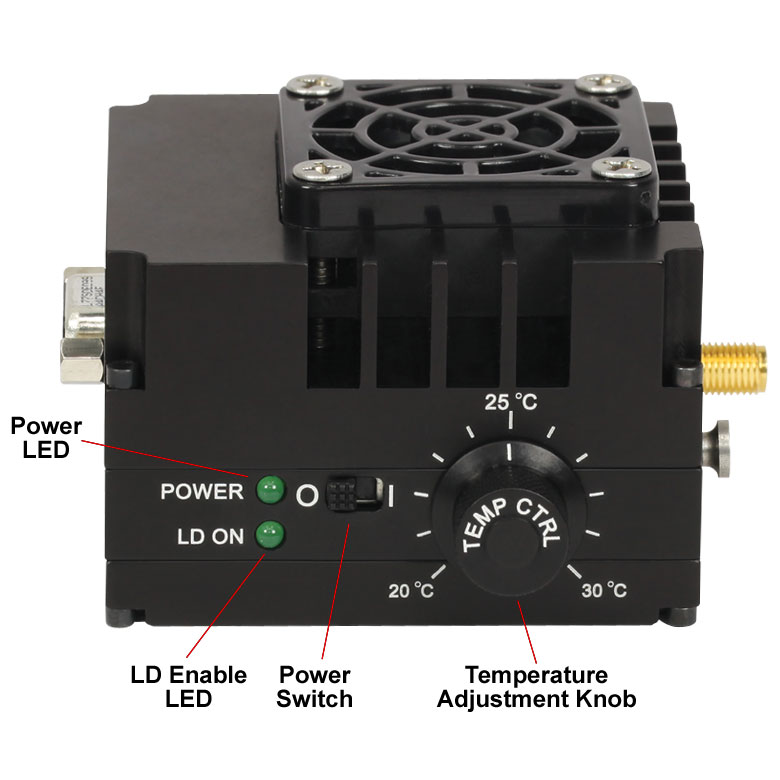

Unit/Benchtop Laser Diode power supplies

These power supply generate current pulses (QCW mode) that can be set between 0 and 500 A, with adjustable pulse width from 20 µs to 3 ms, and an average power (peak power by duty cycle) of up to 1000 W. It is packaged in a self-cooled 3U rack, with a user-friendly front-panel touch-screen interface. This power supply is suited for powering High Power Laser Diodes in a very versatile way, offering several control options, such as internal or external trigger, pulse duration, single shot to any repetition frequency rate.

It also displays applied pulse characteristics: current, voltage and pulse duration. All commands, controls data and pulse measurements are also available through the digital communication bus (I2C, SPI, CAN) or Ethernet (as an option).

The power supply also features all necessary protections to ensure the safety of the laser diodes (and driver) against overcurrent, overvoltage, short and open circuits, and over temperature. All the parameters are user-adjustable.

A second independent channel is offered as an option and can be used either independently or in parallel with the 2nd channel for higher operational current (with the ability to drive diodes up to 1000 A under 100 V). The power supply generates current pulses (QCW mode) adjustable between 0 and 500 A, with pulse durations from 20 µs to 3 ms, at an average power up to 1000 W. The driver is packaged in a self-cooled 3U rack, which includes the AC/DC convertor and a user-friendly front-panel, touch-screen interface.